Crafting Perfection: Real-Time CO2 and Gravity Monitoring in Craft Brewery Fermentation

In the world of craft brewing, precision and efficiency are vital for producing exceptional beers that delight connoisseurs. One of the key aspects of achieving this excellence is fermentation monitoring. In this blog, we’ll explore the advantages of real-time fermentation monitoring through the measurement of produced carbon dioxide (CO2) and specific gravity, examining how this […]

Mastering Beer Filtration: Controlling Dissolved Oxygen for Craft Brewery Excellence

Craft breweries are known for their dedication to quality, flavor, and innovation. In the pursuit of brewing excellence, every aspect of the brewing process matters, including beer filtration. In this blog, we’ll explore the crucial role of dissolved oxygen (DO) control during the filtration process, examining the benefits of DO monitoring, best practices, and cutting-edge […]

Optimizing Craft Beer Fermentation: The Power of Real-Time pH Monitoring

In the world of craft brewing, precision and quality control are paramount. Every step of the brewing process, from mashing to fermentation, plays a crucial role in crafting the perfect brew. In this blog, we delve into the significance of real-time pH monitoring during fermentation, exploring the benefits, challenges, and best practices for craft breweries. […]

Cleaning-in-Place for Craft Breweries

Discussing Manual vs. Automated CIP Processes

Cleaning-in-place (CIP) is a crucial process in the brewery industry to maintain hygiene and ensure product quality by effectively cleaning and sanitizing equipment and pipelines. Both manual and automated CIP procedures are commonly employed, each with its advantages and processes. Breweries choose CIP procedures based on their scale, equipment, and resource availability, often utilizing a […]

Craft Breweries Cleaning-in-Place Best Practices

Automating CIP for Greater Efficiencies

Clean-in-place (CIP) is a crucial process in a craft brewery to maintain high standards of cleanliness and hygiene, ensuring the quality and safety of the beer produced. Here are some best practices for implementing clean-in-place procedures in a craft brewery: Develop a Standard Operating Procedure (SOP): Establish a comprehensive SOP for the CIP process. This […]

Monitoring Dissolved Oxygen in Craft Breweries

Dissolved oxygen (DO) plays a crucial role in a brewery, and its accurate measurement and control are essential for maintaining beer quality and consistency. Today, we’re discussing the uses of DO in a brewery, its importance, and how to best measure it using a high accuracy, zero maintenance solution.

Automating Craft Breweries, Saving Brewers Time and Money

BrewOps is a groundbreaking automation platform that is transforming brewing operations by automating craft breweries…

Optimize Monitoring for Your Brewery Chiller: Don’t Chance it with Your Chiller

A chiller plays a crucial role in controlling and maintaining the temperature of various processes involved in brewing beer. This cooling system helps regulate the temperature of liquids, equipment, and environments to ensure optimal conditions for the brewing process.

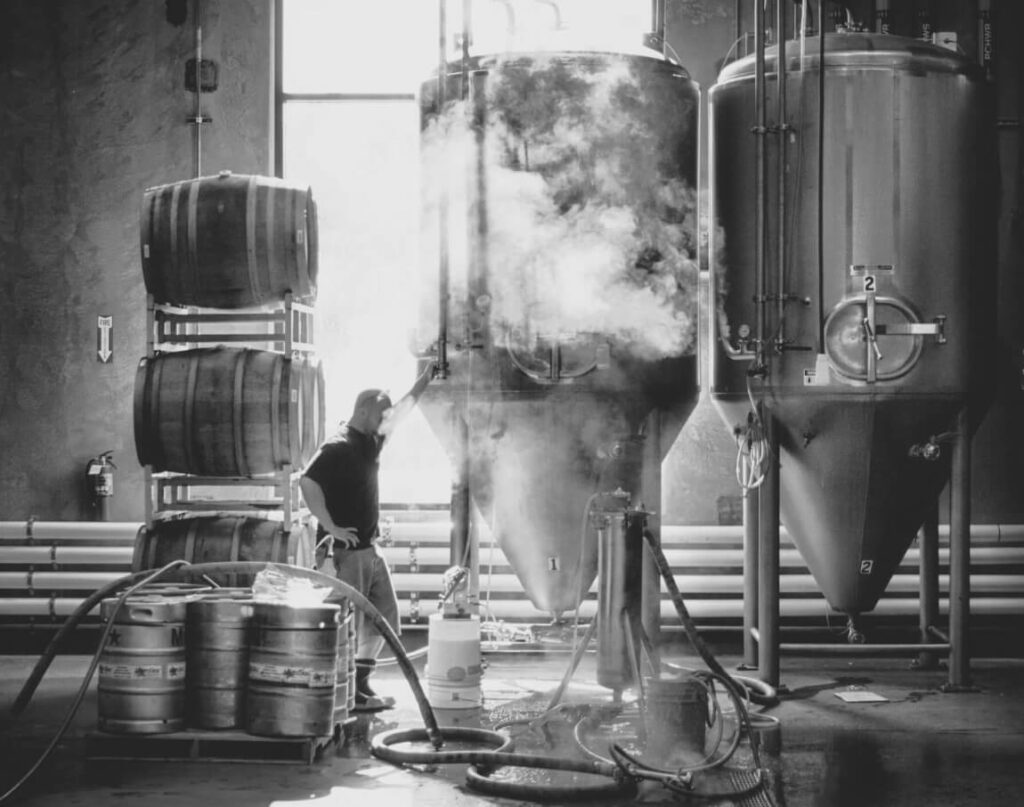

Revolutionizing Brewery Cleaning: The Importance of CO2 Removal & BrewOps Purge

In the thriving world of craft brewing, every detail matters — from the choice of grains to the cleaning of brewing vessels. However, one detail often overlooked is the importance of removing carbon dioxide (CO2) from brewery vessels before performing Clean-in-Place (CIP) cleaning. Failing to do so can have multiple detrimental effects including tank damage, cleaning inefficiency, increased water usage, and skyrocketing labor costs. In today’s post, we’ll delve into these challenges and introduce a groundbreaking solution that elevates transparency, consistency, reduces material waste, and boosts efficiency: The BrewOps Purge.

Protect Your Brewery from Unexpected Downtime: Monitor Your Steam Boilers

Learn how breweries can reduce unexpected downtime by monitoring their steam boilers, understand the importance of boilers in the brewing process, and prevent sporadic failures through preventative maintenance.